Description

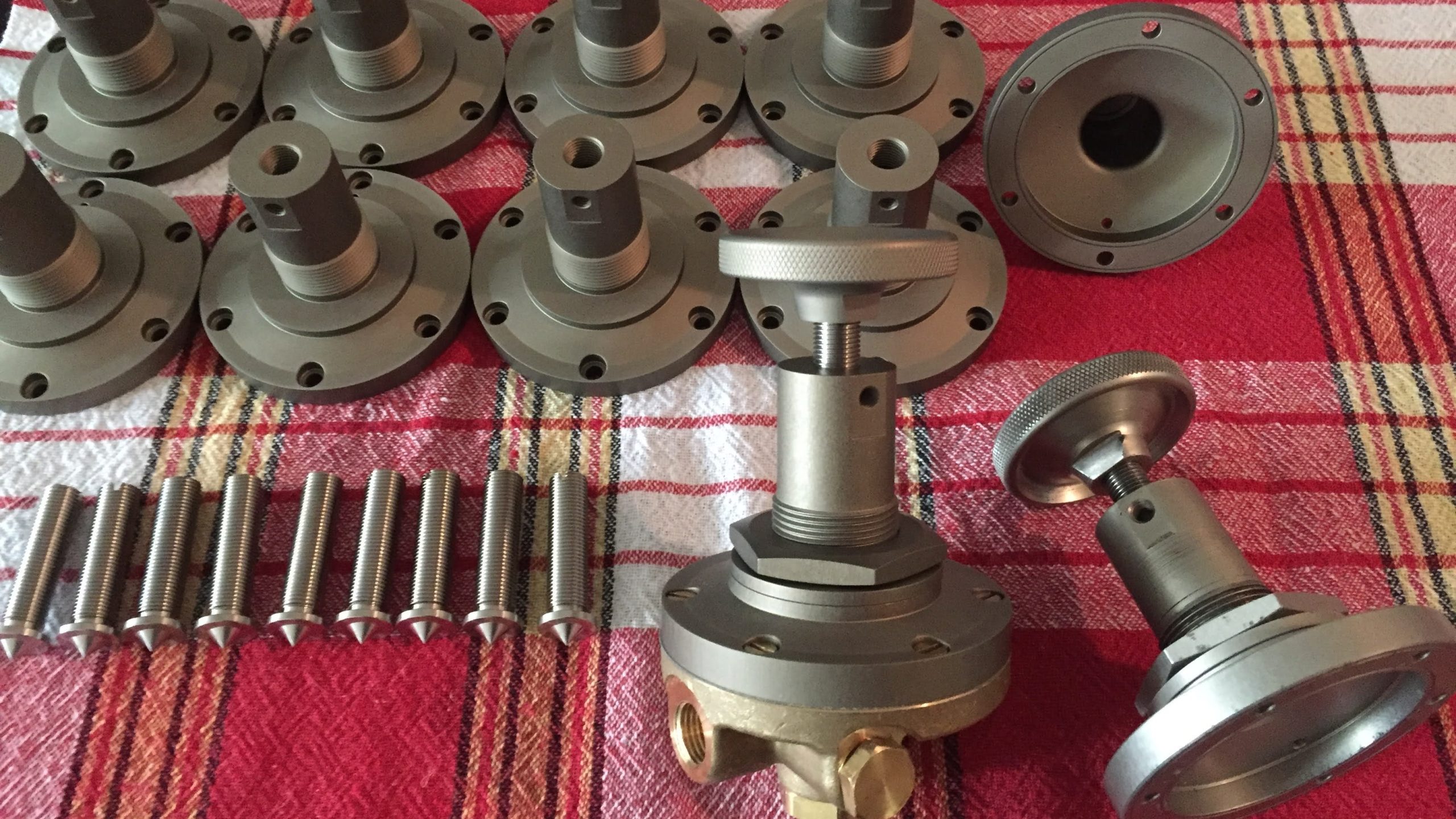

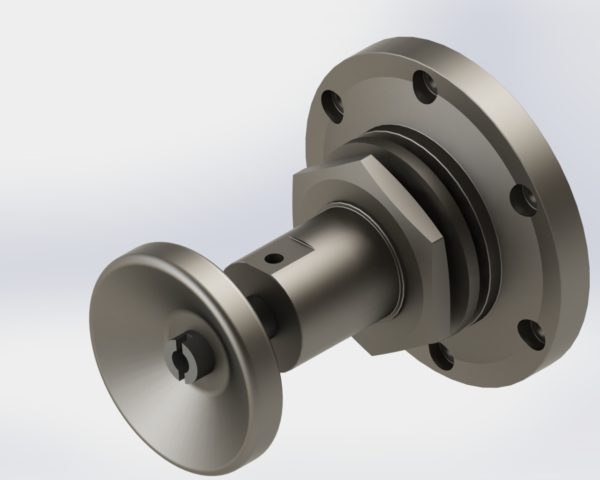

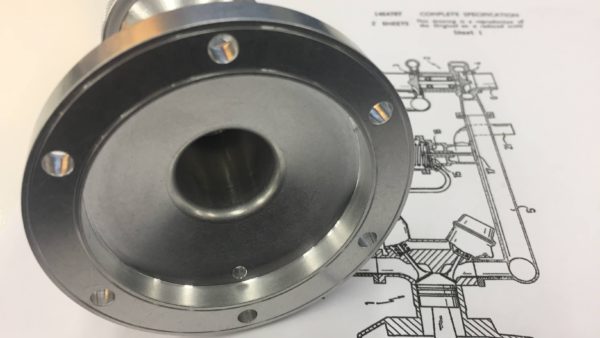

This is a painstakingly accurate replica of a Porsche Adjustable Boost Knob. Porsche actually patented the wastegate (exhaust bypass valve) after a visit to AirResearch in 1971 having figured out a way to improve on the diaphragm valve AirResearch started working with. In some of the photos is an image from that patent--and this valve is #20 in the diagram.I have access to an original which was anodized a bronze colour and proceeded to laser scan the part to make what I feel is a very accurate replica.The hardest part was finding the actual pressure regulator from the original source. It took some digging to generate leads and cold-calling to Germany but I finally located the original source of the pressure regulators, so the most critical part is nailed down.Every aspect of these parts conforms to DIN standards where possible, as I imagine the original might have:

- Threads

- Nut

- Washer

- Knurling

- Across flats dimension on the hand-wheel

- Slot inside the adjustment screw meant to accommodate a flat tip screwdriver

There is a DIN standard for the knurling--which is a rolled knurling, not cut--which offers an equation to compute the after knurling expansion of the part. I was able to use this equation to insure that my part is the exact diameter I wanted when finished.The handwheel and body was laser scanned and processed in Geomagic, then all the actual radii and angles were extracted to be as precise as possible. It was a labour of love.The part is hard anodized which gives a nice and durable finish and closely matches the original part. I assume no one wanted a shiny Aluminium part in the cockpit. I thought the anodizing might be a DIN standard colour as well, but was not convinced in the end. All fasteners are stainless steel except for the M5 jet nut which locks down the nylon-tipped set screw that sets the wheel feel.The regulator comes with M12x1.50 timeserts.The machined components are made in America of 7075 and AISI 303 because the Aluminium material quality is superior to 6061 and I didn't want to see rusty looking black oxide fasteners--they seem to get that way fast when exposed. The parts were tumbled after machining to produce a uniform finish before anodizing and the stainless adjuster screws were passivated per ASTM A380.

I am a mechanical engineer/engine designer with a passion for Porsche having worked at both ANDIAL and PMNA in my formative years. I design internal combustion engine components full time and am starting to work on projects like this in my spare time. I designed and drew these parts in SolidWorks and I toleranced all dimensions and placed GD&T when necessary. I think you will find the feel, fit, and finish to be consistent with a properly engineered component.

Tools required to disassemble/mount/adjust

Wrenches: 41 mm, 22 mm, 17 mm1 14 mm

Allen keys: 6 mm, 3 mm, 2.5 mm

mondre –

Integer dapibus turpis pulvinar nunc porttitor, sed auctor libero posuere. Fusce nisi nunc, porta egestas venenatis ut, sodales a purus. Pellentesque adipiscing enim massa, nec vulputate ante vehicula et. Quisque malesuada feugiat augue a ullamcorper.