cog|design standards

milling - modeling blends & corner radii

scope

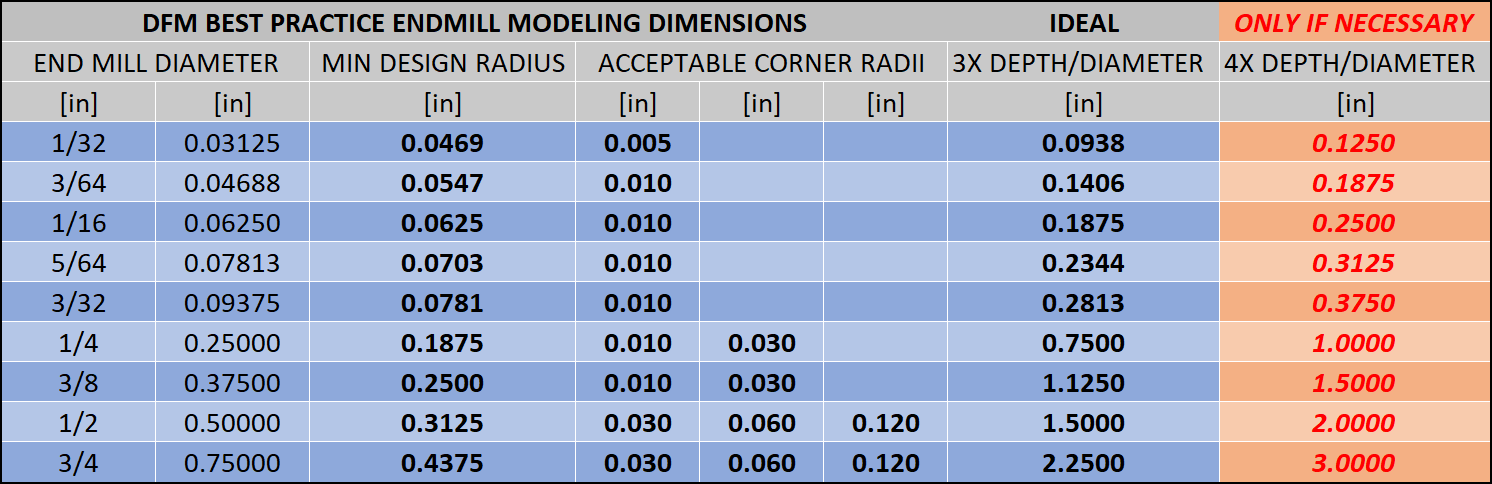

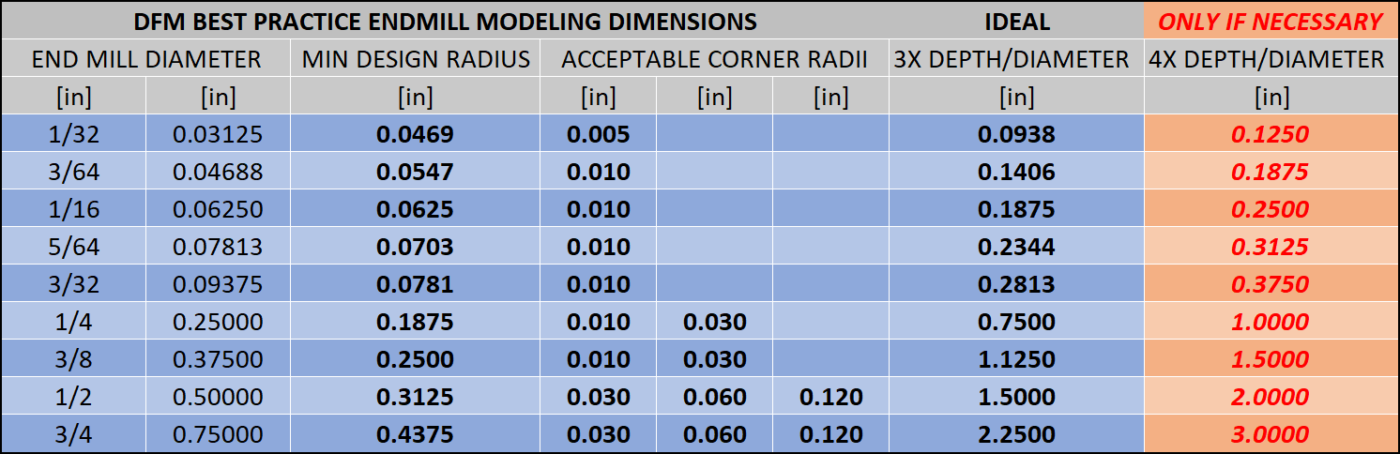

generally speaking, there is more or less a standard range of available endmills one should choose from when designing a part to keep costs as low as possible. furthermore, the depth at which one should intend a machinist to drop that endmill into a part--the depth to diameter ratio--should also be controlled.

design for manufacture

whenever possible, use the largest endmill you possibly can--and try not to switch tools--use that endmill as much as you can in a given part.

minimum design radius

if you intend to create a radius in your part of .250" somewhere--and you can see that you are going to need an endmill to make it, the endmill that is going to make it is not going to be .500" in diameter. for a .500" endmill to make a .250" radius, it will have to stop. It will also use 90° of its cutting surface--neither of which are ideal for both the toolpath/surface finish or the tool itself. for the sake of the tool, the portion that should be cutting should be around 10° or less. for the toolpath, something continuous will produce a nicer surface finish.

if you are trying to get as small a radius as you can in your design--but your depth to diameter ratio is already telling you you're going to need a .500" end mill--the smallest radius you can design in will be .3125". we're taking the radius of the endmill and adding 1/32" for endmills at 3/32" diameter and below, and adding 1/16" for diameters above that. this allows that endmill to properly interpolate the 'minimum design radius.'

acceptable corner radii

all too often i see designers placing sharp corners in their designs. if the part is going to be milled, likely your endmill will have a corner radius at the bottom of it--not a sharp edge. these corner radii are listed in the table and should be selected according to the diameter endmill you intend to use. i often see the sharp corner at the intersection of a part body and its bolted flange--and the sharp corner is close enough to the clearance holes that when an endmill with an actual corner radius makes the cut, the washer for that fastener may crash into the blend.

depth to diameter

the depth of the material you need to cut--the depth of a pocket in a part for instance--will drive what diameter of endmill you can use. i've seen acceptable depth to diameter ratios for endmills be around 3 to 5. the target ratio in the table is 3 or 4. if you need more, talk to a machinist, but this is an ideal place to start.

- i've seen 6" deep Aluminium enclosures with sharp corners all the way down--not manufacturable. if you wanted to machine the inside of a 6" enclosure (the inside of a solid rectangle), you'd probably select a 3/4" end mill so you could drop in 3", and would have to flip the part around to get to the full 6", and the internal blend would need to be 0.4375"--a far cry from a sharp corner, so you'll have to position the internals of the box accordingly.